Solution for SMT Assembly

Inline/Offline Laser Marker

We offer the full range of SMEMA compatible Board Handling & PCB Conveying Systems of high quality & reliability from domestic & overseas manufacturers. Range includes: Magazine Loader/Unloader, Vacuum Loader, PCB Cleaner, Link, Inspection, Shuttle, Traverse, Wave Solder inlet & Outlet, PCB Assembly Conveyor etc.. These systems can handle a variety of board sizes, shapes, and thicknesses, and are designed to integrate seamlessly into production lines. Customisable solutions also available.

Solder Paste Printer

Manufacturer is Global leading supplier, having 25+ years of Experience in the Printing technology. The machines are built to cater for the all the segment of Electronics manufacturing industry caring for small, medium large to Extra Large/Long Board requirements. Our OEM guarantees the high quality and processing standards worldwide., the products are high end but economical, repeatable and competitive.

Solder Paste Jet Printer/Dispenser

ESSEMTEC AG from Switzerland builds & delivers High-speed & Flexible dispensing solutions, the systems are robust, accurate and reliable, built with advanced and future ready features to cater and meet next-generation manufacturing requirements.

3D Solder Paste Inspection

Our OEM products are high Performance 3D Solder Paste & Solder Joint Inspection in the Industry, the features and functions are more advanced to take care of future manufacturing needs. Extremely fast and highly accurate in-line inspection, high throughput, efficiency & producibility, Quicker program generation, higher first pass yield, negligible false calls rate adds to the feature list.

High Speed Mounter

We offer High speed Chip mounter from Panasonic, which does not need introduction. Offers variety of models to establish Efficiency, Throughput and Performance. Can cater to latest and upcoming component handling and assembly requirements. These systems are best suitable for Mid & high-volume production, high throughput, repeatability and accuracy are the advantages of Panasonic placement systems.

Flexible Mounter

ESSEMTEC AG from Switzerland builds & delivers State of Art Flexible & Versatile SMD component placement solutions. A single machine can Dispense, Place & Inspect. The product portfolio caters to NPI, High Mix Low Volume, Low, Mid & Higher volume production requirements for electronics manufacturing. Machines are scalable to manufacturing capacity expansions. Essemtec machines are best known for easy adaptability to your current & future requirements and onsite enhancement feasible.

Reflow Soldering Machine

We offer High Productive, Energy-efficient, Trouble free Reflow soldering systems for the Electronics, Semicon & Solar Industries. A range of standard and customised reflow soldering systems (convection, condensation or vacuum) are available. These reflow soldering systems are best suitable for Low, Mid & High-volume production requirements. Heat distribution / recirculation repeatability, Flux management system, Nitrogen ready and ease of maintenance are the best qualities of our OEM solutions.

2D/3D Automatic Optical Inspection

Our OEM products are high Performance 3D Solder Paste & Solder Joint Inspection in the Industry, the features and functions are more advanced to take care of future manufacturing needs. Extremely fast and highly accurate in-line inspection, high throughput, efficiency & producibility, Quicker program generation, higher first pass yield, negligible false calls rate adds to the feature list.

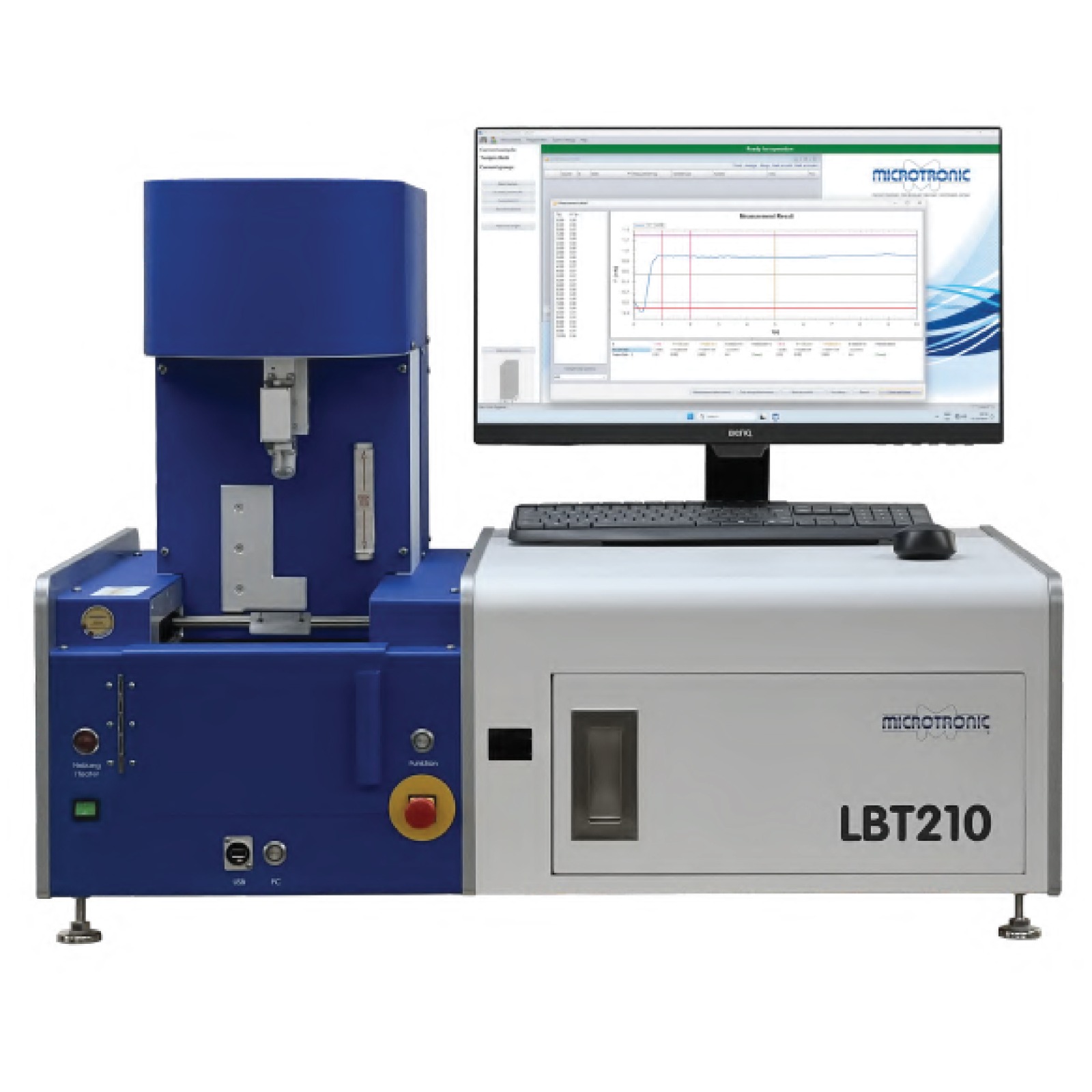

Solderability Tester (Surface Wetting by Solder)

ZEVAC SMD/BGA Rework Machine

ZEVAC AG, Switzerland develops and produces machines for the component placement and component interconnection technology including soldering processes, focusing on printed circuit board repair systems within the manufacturing process of the electronics industry. With 45+ years of Experience Zevac is specialised in rework of all electronic component in SMT or THT. Zevac Products known for Precision, Reliable and Flexible.

ZEVAC Automatic SMD/BGA Rework Machine

ZEVAC AG, Switzerland develops and produces machines for the component placement and component interconnection technology including soldering processes, focusing on printed circuit board repair systems within the manufacturing process of the electronics industry. With 45+ years of Experience Zevac is specialised in rework of all electronic component in SMT or THT. Zevac Products known for Precision, Reliable and Flexible.

MSTECH Offline Depaneling

MSTECH South Korea, is a leading Global supplier of PCB Singulation and OFFLINE Depaneling solutions.

Sawing, Routing and laser depaneling are the key product categories. Offline systems are best suitable for stand-alone applications or where robotic systems are in-place. MSTECH offers productivity with Offline PCB depaneling system with Single Spindle to upto 4 Spindle configuration and Single table to dual table as Standard, Moebius system enables “ZERO” machine idle time. High efficiency dust collecting system for 0% remaining dust

MSTECH Inline Depaneling

MSTECH South Korea, is a leading Global supplier of PCB Singulation and OFFLINE Depaneling solutions.

Sawing, Routing and laser depaneling are the key product categories. Offline systems are best suitable for stand-alone applications or where robotic systems are in-place. MSTECH offers productivity with Offline PCB depaneling system with Single Spindle to upto 4 Spindle configuration and Single table to dual table as Standard, Moebius system enables “ZERO” machine idle time. High efficiency dust collecting system for 0% remaining dust.

Conformal Coating Machine

Wide range of Conformal coating solutions for wide variety of customer applications are offered. Machine range from tabletop, offline & inline applications. Variety of materials can be handled with 3 0r 3 Axis machines. Curing ovens are also available.

Conformal Coating Inspection

Standard & tailor-made systems are available to meet the diverse requirements of conformal coating inspection. Special UV LEDs and other features ensure the right contrast with the UV-sensitive conformal coating. Precise detection of Coating Voids, Fast inspection program creation, Easy adoptability to various coating applications and 3D spot measurement are the important features.

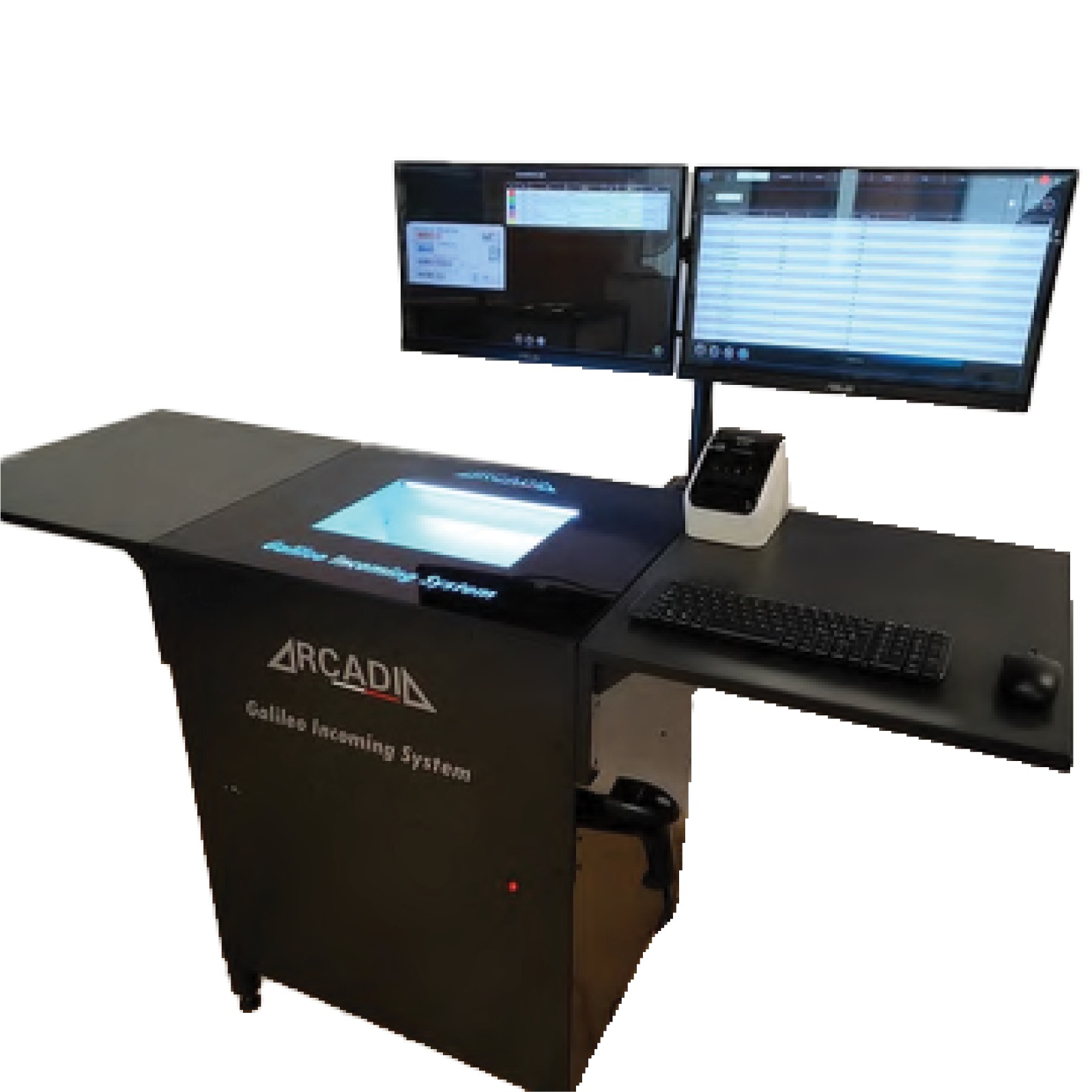

Incoming Scanning

ARCADIA offers smart component management solutions. Designed to simplify and automate the management of components within the company. These systems reduce the storage time from minutes to few seconds, optimize the necessary space for their storage and eliminate machine tooling errors. Registering component data quickly, generating component label data as per the customer requirements, avoid labelling errors. Smart storage solutions enable machine operator to identify the required components / parts loading in-advance to eliminate the machine idle time.

4D Profiler & Vibration Measurement

MES & Traceability solutions

Intelizest delivers Economical MES & Traceability solutions for Material In-warding, Shop floor and Warehouse management within the factory.

Solutions address major pain points of our customers using expensive MES and traceability solutions. Our MES solution covers all the areas and activities of Procurement, Incoming goods, Manufacturing and Warehouse management modules.

Wave Soldering

We offer single or dual wave soldering machines from leading manufacturers in the industry, with varying PCBA handling capabilities and solder pot sizes. Other features include multi stage Finger conveyor, multi stage Pre heaters and other suitable configurations for low to large Production volume.

Board Handling Systems

We offer the full range of SMEMA compatible Board Handling & PCB Conveying Systems of high quality & reliability from domestic & overseas manufacturers. Range includes: Magazine Loader/Unloader, Vacuum Loader, PCB Cleaner, Link, Inspection, Shuttle, Traverse, Wave Solder inlet & Outlet, PCB Assembly Conveyor etc.. These systems can handle a variety of board sizes, shapes, and thicknesses, and are designed to integrate seamlessly into production lines. Customisable solutions also available.

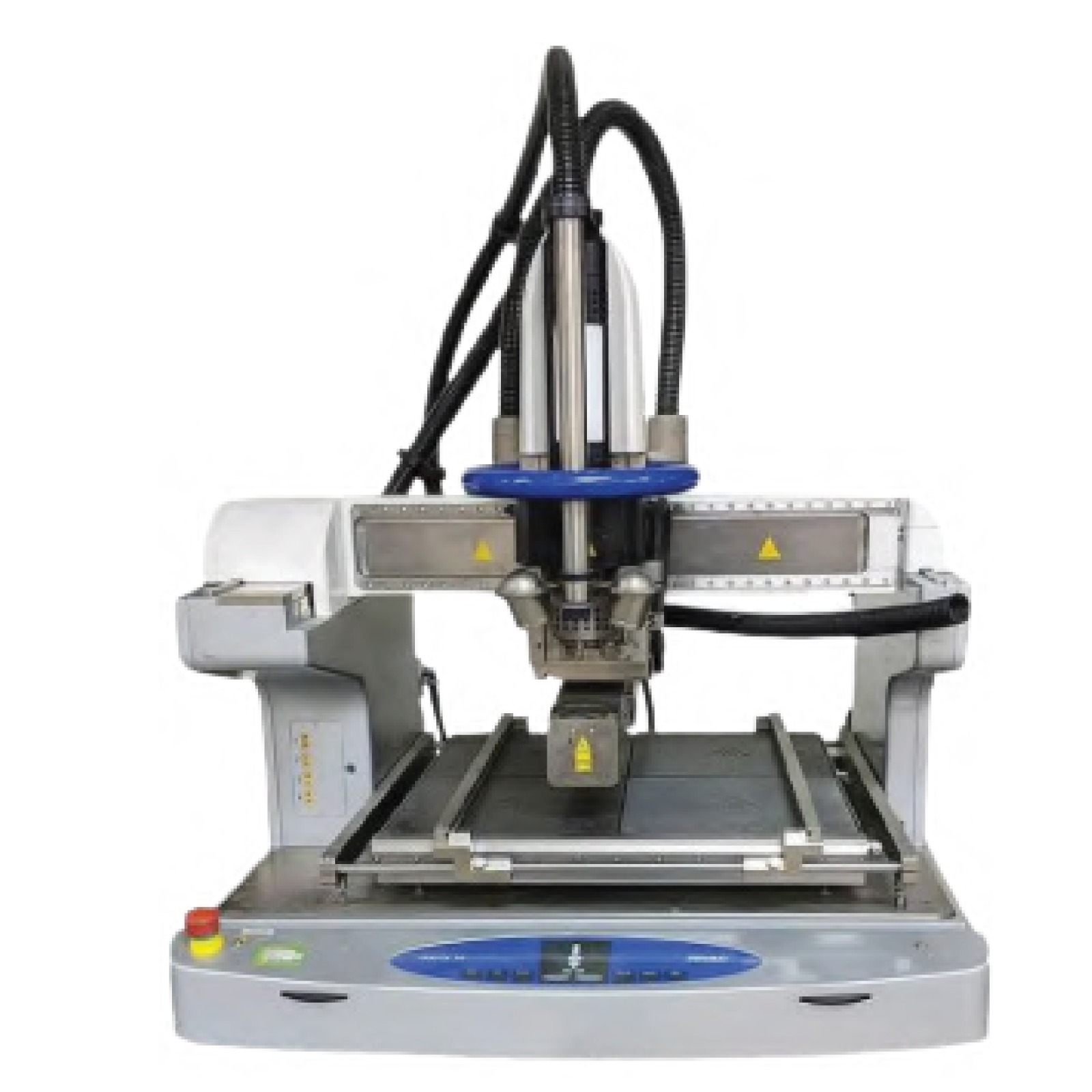

Robotic Soldering

Ergonomic, Reliable, Standard & Configured machines are offered on behalf of our OEMs, that meet the specific applications of our customers.

ELMOTEC is the OEMs for High end Robotic Soldering Machines who has Design, Development and production of electric drive controlled soldering equipment and machines is the main focus. ELMOTEC specializes in solving application problems when using the latest and most advanced technology.

Stencil & PCBA cleaning machine

We offer renowned brand / OEM for the Stencil cleaning. OEM is engaged in research, development and manufacturing of Automatic Stencil & PCBA Cleaning equipment. Single or Dual stage Stencil Cleaning machines for Solder paste and/or Glue applications are offered. Best part is it work without Electricity & IPA can be used. The technology and equipment are widely used in high-tech industries such as Electronics, Semiconductors, Automotive Electronics, Consumer electronics, Energy & Power Electronics and others.

Stencil & PCBA cleaning machine

We offer renowned brand / OEM for the Stencil cleaning. OEM is engaged in research, development and manufacturing of Automatic Stencil & PCBA Cleaning equipment. Single or Dual stage Stencil Cleaning machines for Solder paste and/or Glue applications are offered. Best part is it work without Electricity & IPA can be used. The technology and equipment are widely used in high-tech industries such as Electronics, Semiconductors, Automotive Electronics, Consumer electronics, Energy & Power Electronics and others.

Stencil & PCBA cleaning machine

We offer renowned brand / OEM for the Stencil cleaning. OEM is engaged in research, development and manufacturing of Automatic Stencil & PCBA Cleaning equipment. Single or Dual stage Stencil Cleaning machines for Solder paste and/or Glue applications are offered. Best part is it work without Electricity & IPA can be used. The technology and equipment are widely used in high-tech industries such as Electronics, Semiconductors, Automotive Electronics, Consumer electronics, Energy & Power Electronics and others.

Offline PCB Depaneling

MSTECH South Korea, is a leading Global supplier of PCB Singulation and OFFLINE Depaneling solutions.

Sawing, Routing and laser depaneling are the key product categories. Offline systems are best suitable for stand-alone applications or where robotic systems are in-place. MSTECH offers productivity with Offline PCB depaneling system with Single Spindle to upto 4 Spindle configuration and Single table to dual table as Standard, Moebius system enables “ZERO” machine idle time. High efficiency dust collecting system for 0% remaining dust.

Stencil & PCBA cleaning machine

We offer renowned brand / OEM for the Stencil cleaning. OEM is engaged in research, development and manufacturing of Automatic Stencil & PCBA Cleaning equipment. Single or Dual stage Stencil Cleaning machines for Solder paste and/or Glue applications are offered. Best part is it work without Electricity & IPA can be used. The technology and equipment are widely used in high-tech industries such as Electronics, Semiconductors, Automotive Electronics, Consumer electronics, Energy & Power Electronics and others.

Laser Marking Machine

We offer the full range of SMEMA compatible Board Handling & PCB Conveying Systems of high quality & reliability from domestic & overseas manufacturers. Range includes: Magazine Loader/Unloader, Vacuum Loader, PCB Cleaner, Link, Inspection, Shuttle, Traverse, Wave Solder inlet & Outlet, PCB Assembly Conveyor etc.. These systems can handle a variety of board sizes, shapes, and thicknesses, and are designed to integrate seamlessly into production lines. Customisable solutions also available.